As automotive technology advances, automotive PCB boards have become more important as a crucial electronic part. Unlike regular PCB boards, car PCB boards must meet strict safety, reliability, and stability standards. This article will discuss the differences between car PCB boards and regular PCB boards, the uses of car PCB boards, and the future trends in car PCB board development.

Differences between Automotive PCB Boards and Regular PCB Boards

In terms of design and manufacturing, there are several differences between automotive PCB boards and regular PCB boards:

1.PCB Materials

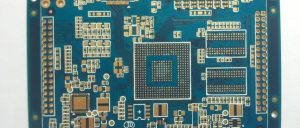

Automotive PCB boards and regular PCB boards have differences in material selection. Regular PCB boards typically use FR-4 fiberglass material, while automotive PCB boards require higher-level materials such as FR-4 HTG with better high-temperature tolerance or polyimide materials. This is because automotive PCB boards need better stability and reliability in high-temperature environments.

2.PCB Thickness

Automotive PCB boards have stricter requirements. Regular PCB boards are usually 0.2-3.0mm thick, while automotive PCB boards are typically 0.6-3.2mm thick. This is because automotive electronic components work in harsher environments, so automotive PCB boards must be more durable and stable in terms of thickness.

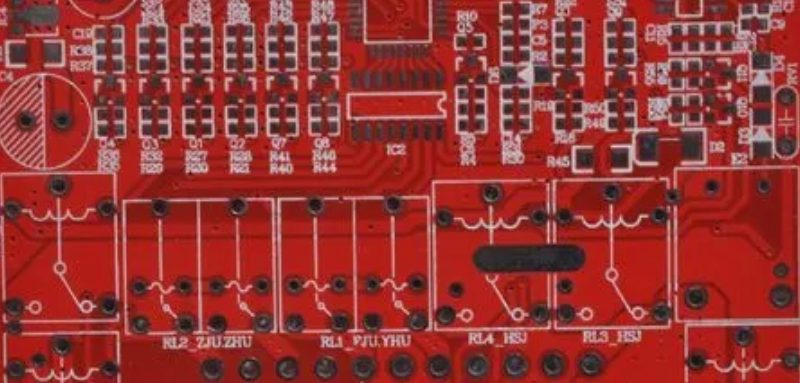

3.Special PCB Processes

There are also differences in process requirements between automotive PCB boards and regular PCB boards. Due to the need to withstand more severe working conditions and vibration impacts, automotive PCB boards have higher process requirements. For example, automotive PCB boards require stricter soldering and treatments such as waterproofing, dustproofing, shock resistance, and impact resistance to ensure circuit stability and reliability. In addition, automotive PCB boards also need to meet higher fire resistance ratings and corrosion resistance to effectively reduce the failure rate of automotive circuits.

4. PCB Circuit Design

When designing PCB circuits for automotive use, it is important to ensure circuit safety, reliability, durability, and stability. This means taking into account factors like temperature, humidity, and dust that are relevant to the automotive work environment.

Application of Automotive PCB Boards

Automotive PCB boards are widely used in the fields of automotive electronics, car audio, car multimedia, and car navigation. Automotive PCB boards not only improve the safety and reliability of automotive circuits,but also enhance their efficiency and performance. The applications of automotive PCB boards include, but are not limited to, the following:

1. Car Electronics

There are many electronic devices in cars, such as car computers, car audio systems, and car multimedia systems. These devices require efficient and reliable automotive PCB boards to support them to achieve optimal performance.

2. Car Navigation

Car navigation represents the new generation of intelligent transportation, which helps drivers plan the best routes and avoid traffic congestion and other conditions. Automotive PCB boards, as an important component of car navigation, can improve its performance and accuracy.

3. Car Safety

The safety systems in cars include various sensors, controllers, and transmission devices. Safety systems must achieve a high level of reliability and security to ensure passenger safety. This requires automotive PCB boards to withstand extreme working environments such as temperature and humidity to ensure the normal operation of the systems.

Future Development Trends of Automotive PCB Boards

The future of automotive PCB boards will be smarter, easier to use, and safer. These trends will mainly focus on:

1. Intelligence

Automotive PCB boards of the future will be more connected to other vehicle devices and will be smarter. For instance, they may work together with internal sensors in vehicles and use artificial intelligence algorithms to adjust all vehicle devices for a smoother driving experience.

2. Convenience

Future automotive PCB boards will use advanced materials and processes to improve stability and reliability. This will make vehicle maintenance and repair more convenient, reducing operational costs.

3. Safety

Safety is a crucial concern in automotive electronics. Future automotive PCB boards will prioritize the safety performance of automotive electronics, ensuring a safe driving experience.

There are big differences between automotive PCB boards and regular PCB boards,when it comes to the materials used, how they’re made, how well they work in different environments, and how reliable they are. Automotive PCB boards are really important in the world of car electronics and have a lot of potential for growth. As car electronics keep getting better and better, the demand for automotive PCB boards will go up even more. Automotive PCB boards have to be really safe, reliable, and stable. They don’t just make car circuits work better and more efficiently, they also make cars perform better and give people a better driving experience. In the future, automotive PCB boards will be even smarter, more convenient, and safer, making traveling easier and more secure for everyone.

Fuxin specializes in Contract Manufacturing of Electronic Products, from prototypes to small & medium production volumes of PCB Assembly & Turnkey assembly/ box build. Our one-stop PCBA/OEM service support multiple markets, including industrial,medical,communications network, automotive,multimedia(Fuxin media),consumer electronics,clean technology and oil&gas.

Recent Comments