Introduction: What is a Curved PCB?

A curved PCB is an advanced circuit board designed to bend or flex, enabling innovative electronic designs that rigid boards can’t achieve. By combining rigid (PWB) and flexible (FPC) materials, these PCBs allow for 3D circuit integration, making them essential for foldable smartphones, wearables, medical devices, and automotive electronics.

In this guide, we’ll explore:

✔ Different types of curved PCBs

✔ Key benefits and applications

✔ How they compare to traditional rigid PCBs

✔ Industry-leading specifications

Types of Curved PCBs & Their Key Features

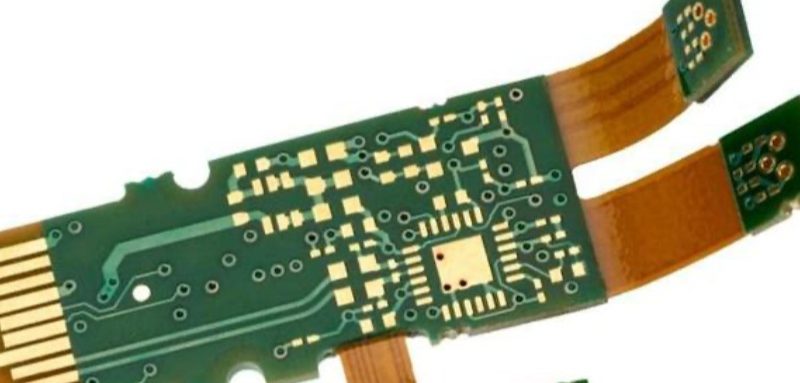

1. Advanced Flexible-Rigid PCB (Best for Foldable Devices)

A hybrid of rigid and flexible layers, this type is ideal for ultra-thin, high-performance electronics.

✅ Thinnest option: Just 0.3mm (4-layer) or 0.39mm (6-layer)

✅ Extreme flexibility: Can bend 180° with a 3mm radius (200,000+ folds)

✅ High-density wiring: 0.075mm trace spacing for compact designs

✅ Blind & buried vias: Enables “chip-on-hole” mounting

Best for: Foldable phones, wearables, medical implants

2. Flexible Composite Multilayer PCB (Space-Saving Design)

Uses internal flexible layers to connect rigid sections, reducing weight and improving reliability.

✅ 0.5mm pitch CSP/IC mounting

✅ Stacked vias for ultra-fine wiring

✅ Lighter than traditional rigid-flex boards

Best for: Drones, aerospace systems, compact IoT devices

3. Ruggedized Curved PCB (For Harsh Environments)

Built to withstand extreme temperatures, vibrations, and moisture.

✅ 0.5mm pitch components

✅ Military-grade durability

✅ Supports SMT, COB, and fine-pattern designs

Best for: Automotive, industrial robots, defense systems

4. Standard Flexible PCB (Basic Bendable Circuits)

A fully flexible circuit board for dynamic bending applications.

✅ Chip-on-Flex (COF) & wire-bonding support

✅ Reduces assembly steps

✅ Improves reliability in moving parts

Best for: Cameras, printers, foldable displays

Why Use Curved PCBs? Key Benefits

| Advantage | How It Helps |

|---|---|

| 3D Circuit Design | Fits into unconventional shapes (curved displays, wearables) |

| Space & Weight Savings | 30-50% lighter than rigid PCBs with connectors |

| Enhanced Durability | Survives bending, folding, and vibrations |

| Higher Reliability | Fewer connectors → less failure risk |

| Simplified Assembly | Reduces wiring complexity in compact devices |

Top Applications of Curved PCBs

📱 Consumer Electronics – Foldable phones, smartwatches, VR headsets

🚗 Automotive – Curved dashboards, LED lighting, sensors

⚕️ Medical – Implantable devices, flexible biosensors

🛰️ Aerospace – Lightweight satellites, UAVs

🏭 Industrial IoT – Robotic arms, bendable sensors

Curved PCB vs. Traditional Rigid PCB

| Feature | Curved PCB | Rigid PCB |

|---|---|---|

| Flexibility | ✅ Bendable & foldable | ❌ Rigid |

| Weight | ⚡ Lighter (no connectors) | ⚖️ Heavier |

| Durability | 🛡️ Better for dynamic use | 🏗️ Prone to cracking under stress |

| Cost | 💰 Higher (complex manufacturing) | 💵 Lower |

| Best For | Wearables, foldables | Computers, home appliances |

Conclusion: Are Curved PCBs Right for Your Project?

Curved PCBs are revolutionizing electronics by enabling:

✔ Thinner, lighter, and more flexible devices

✔ Superior reliability in moving parts

✔ Innovative designs (foldable phones, wearables, medical tech)

Ideal if you need:

-

Space-saving 3D circuits

-

Durability in bending/folding applications

-

High-density wiring in compact devices

Need help selecting the right curved PCB? Contact our experts for a free consultation on materials, stack-up, and manufacturing processes!

Recent Comments