Introduction: Understanding PCB Technologies

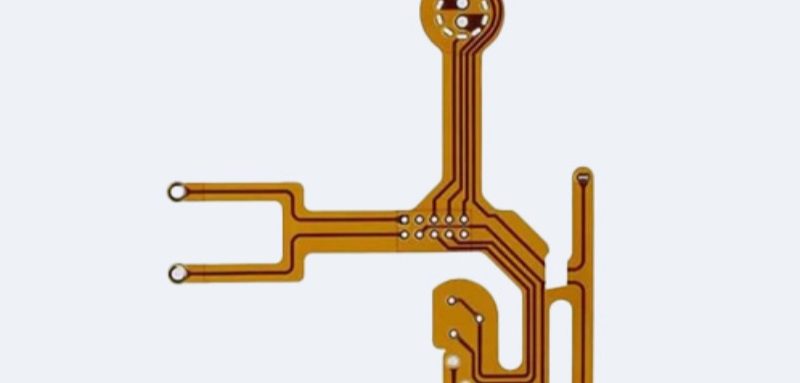

Printed Circuit Boards (PCBs) form the foundation of modern electronics, with flexible PCBs revolutionizing product design. Unlike traditional rigid PCBs, flexible circuit boards offer unique advantages for cutting-edge applications – from foldable smartphones to advanced medical devices. This comprehensive guide compares flexible and rigid PCBs, explores their applications across industries, and highlights why engineers increasingly prefer flexible PCB solutions.

Key Differences: Flexible vs. Rigid PCBs

Material Composition

- Flexible PCBs: Use polyimide (PI) or polyester films (PET/PEEK)

- Rigid PCBs: Typically FR4 fiberglass or composite epoxy materials

Performance Comparison

| Feature | Flexible PCBs | Rigid PCBs |

|---|---|---|

| Bendability | Dynamic (up to 500,000 bend cycles) | None |

| Weight | 70% lighter | Standard weight |

| Thickness | 0.1-0.3mm | 1.6mm standard |

| Temperature Range | -200°C to 400°C | -50°C to 150°C |

| Vibration Resistance | Excellent | Moderate |

| Space Efficiency | 3D configuration possible | Planar only |

Manufacturing Considerations

- Flex PCBs require specialized processes (laser drilling, roll-to-roll etching)

- Rigid PCBs have simpler, more cost-effective fabrication

- Flex PCB assembly demands higher precision

Top 6 Applications of Flexible PCBs in 2025

1. Consumer Electronics Revolution

Flexible circuit boards enable:

- Foldable smartphones (Samsung Galaxy Z series)

- Ultra-thin laptops and tablets

- Wearable devices (Apple Watch, Fitbit)

- Flexible OLED displays

2. Automotive Innovations

Modern vehicles use flex PCBs for:

- Advanced Driver Assistance Systems (ADAS)

- Battery management in EVs

- LED lighting systems

- Dashboard electronics

3. Aerospace & Defense Solutions

Key applications include:

- Avionics systems (Boeing 787 Dreamliner)

- Satellite communications

- Military drone electronics

- Space exploration equipment

4. Medical Breakthroughs

Flexible PCBs power:

- Wearable health monitors

- Implantable devices (pacemakers)

- Diagnostic equipment (endoscopic capsules)

- Prosthetic limb electronics

5. Industrial & IoT Applications

Industrial uses feature:

- Robotics control systems

- Industrial automation sensors

- Smart factory equipment

- 5G network components

6. Emerging Technologies

Future applications:

- Stretchable electronics

- Bio-integrated devices

- Smart clothing

- Flexible solar panels

Why Choose Flexible PCBs? 5 Key Benefits

- Space Optimization – 60% reduction in required space vs rigid PCBs

- Weight Reduction – Critical for aerospace and portable devices

- Enhanced Reliability – Fewer connectors mean fewer failure points

- Superior Durability – Withstands millions of bend cycles

- Thermal Performance – Excellent heat dissipation in compact designs

Challenges & Solutions

Challenge 1: Higher Initial Cost

- Solution: Long-term savings through reduced assembly costs

Challenge 2: Complex Design Requirements

- Solution: Work with experienced flex PCB manufacturers

Challenge 3: Limited Layer Count

- Solution: Consider rigid-flex hybrid designs

Future Trends in Flexible PCB Technology

- 3D Printed Electronics – Rapid prototyping for flex circuits

- Biodegradable Substrates – Eco-friendly medical applications

- Nano-material Integration – Enhanced conductivity and flexibility

- AI-Optimized Designs – Machine learning for improved layouts

Conclusion: The Future is Flexible

As electronics continue evolving toward smaller, more durable, and innovative form factors, flexible PCBs are becoming the solution of choice across industries. While rigid PCBs remain important for standard applications, flexible circuit technology offers unparalleled advantages for cutting-edge products.

Key Takeaways:

- Flex PCBs enable revolutionary product designs

- Offer superior performance in demanding environments

- Are becoming more cost-effective at scale

- Will power next-generation electronic devices

For engineers and product designers, understanding flexible PCB capabilities is essential for staying competitive in today’s fast-moving electronics landscape.

Fuxin Electronic Technology specializes in Contract Manufacturing of Electronic Products, from prototypes to small & medium production volumes of PCB Assembly & Turnkey assembly/ box build. Our one-stop PCBA/OEM service support multiple markets, including industrial,medical,communications network, automotive,multimedia,consumer electronics,clean technology and oil&gas.