In the fast-paced world of electronics manufacturing, Turnkey PCB Assembly has become a go-to solution for businesses looking to simplify production and reduce time-to-market. China, a global leader in electronics manufacturing, offers some of the most reliable and cost-effective turnkey PCB assembly services. This guide will walk you through everything you need to know about turnkey PCB assembly, from its benefits and processes to challenges and future trends.

What is Turnkey PCB Assembly Manufacturing?

Turnkey PCB Assembly Manufacturing is a one-stop service where a single provider handles every step of PCB production. From sourcing components to assembling and testing the final product, the manufacturer takes care of it all. This means you can focus on designing and marketing your product while leaving the complexities of production to the experts.

What Does “Turnkey” Mean in PCB Assembly?

The term “turnkey” means the manufacturer provides a complete, ready-to-use solution. In PCB assembly, this includes:

Design Review: Ensuring your PCB design is optimized for manufacturing.

Component Sourcing: Procuring all necessary parts.

PCB Fabrication: Creating the bare circuit board.

Pcb Assembly: Placing and soldering components onto the board.

Testing: Verifying the functionality and quality of the assembled PCB.

Delivery: Shipping the finished product to your doorstep.

This end-to-end service saves you time, reduces hassle, and ensures a high-quality final product.

What Does PCB Mean?

PCB stands for Printed Circuit Board, the backbone of most electronic devices. It’s a flat board made of insulating material (like fiberglass) with conductive pathways etched onto its surface. These pathways connect electronic components such as resistors, capacitors, and microchips to create a functional circuit.

Partial Turnkey vs. Full Turnkey PCB Assembly

When choosing a turnkey PCB assembly service, you’ll typically have two options:

Partial Turnkey: You supply some components, and the manufacturer handles the rest. This is ideal if you have specific parts or want more control over the process.

Full Turnkey: The manufacturer manages everything, from sourcing components to delivering the finished product. This is perfect for businesses that want a hands-off approach.

Turnkey PCB Assembly vs. Consignment PCB Assembly

Here’s how these two models compare:

Turnkey PCB Assembly:

The manufacturer handles everything, including component sourcing. This is great for businesses that want to minimize their involvement.

Consignment PCB Assembly:

You provide all the components, and the manufacturer only handles the assembly. This is ideal if you already have a supply chain or need specialized parts.

Top Benefits of Turnkey PCB Assembly

Saves Time: By outsourcing the entire process, you can focus on other aspects of your business.

Reduces Costs: Manufacturers often get better prices on components, which can lower your overall expenses.

Ensures Quality: Rigorous testing and quality control mean you get a reliable product.

Simplifies Logistics: One provider handles everything, reducing complexity.

Scales Easily: Whether you need 100 or 10,000 units, turnkey services can handle it.

The Turnkey PCB Assembly Process: A Step-by-Step Breakdown

Here’s what the turnkey PCB assembly process typically looks like:

Design Review: The manufacturer checks your design for any issues and suggests improvements.

Component Sourcing: All necessary parts are sourced from trusted suppliers.

PCB Fabrication: The bare circuit board is manufactured.

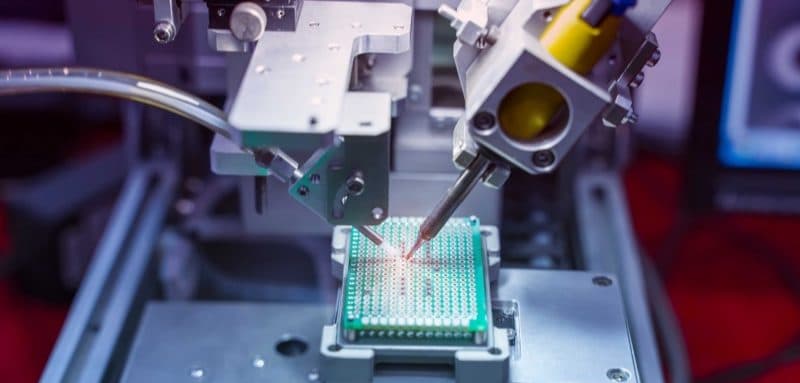

Assembly: Components are placed and soldered onto the board using advanced techniques like SMT (Surface Mount Technology) or THT (Through-Hole Technology).

Testing: The assembled PCB is tested to ensure it works perfectly.

Packaging and Delivery: The finished product is packaged securely and shipped to you.

Turnkey PCB Assembly Standards

To ensure high-quality results, turnkey PCB assembly services follow industry standards such as:

IPC-A-610: Guidelines for electronic assembly quality.

ISO 9001: Standards for quality management systems.

RoHS Compliance: Ensures the use of environmentally friendly materials.

Types of Turnkey PCB Assembly Services

Turnkey PCB assembly services can handle a variety of needs, including:

Single-Sided PCB Assembly: Components are placed on one side of the board.

Double-Sided PCB Assembly: Components are placed on both sides.

Multilayer PCB Assembly: For complex circuits with multiple layers.

SMT Assembly: Ideal for small, high-density components.

THT Assembly: Suitable for larger, more durable components.

Challenges in Turnkey PCB Assembly

While turnkey PCB assembly offers many benefits, there are some challenges to be aware of:

Component Shortages: Global supply chain issues can delay production.

Quality Control: Ensuring consistency across large production runs can be tricky.

Communication Barriers: Working with international manufacturers may require clear communication.

Cost Management: Balancing quality and cost can be challenging, especially for complex designs.

How Much Does Turnkey PCB Assembly Cost?

The cost of turnkey PCB assembly depends on several factors, including:

PCB Complexity: More layers and components increase costs.

Component Prices: High-end or rare components can be expensive.

Order Volume: Larger orders typically reduce per-unit costs.

Testing Requirements: Additional testing may increase costs.

The Future of Turnkey PCB Assembly

The turnkey PCB assembly industry is evolving rapidly, with trends like:

Automation: Increased use of robotics for precision and efficiency.

Sustainability: Eco-friendly materials and processes are becoming more common.

Miniaturization: Demand for smaller, more complex PCBs is growing.

AI and IoT: Smart manufacturing and real-time monitoring are improving quality control.

How to Get a Quote for Turnkey PCB Assembly Services

Getting a quote for turnkey PCB assembly is easy. Just follow these steps:

Prepare Your Design Files: Provide Gerber files, a Bill of Materials (BOM), and assembly drawings.

Specify Your Requirements: Include details like PCB type, quantity, and testing needs.

Contact Manufacturers: Reach out to multiple providers for quotes.

Compare Offers: Look at costs, lead times, and services.

Negotiate Terms: Discuss pricing, warranties, and support.

Conclusion

Turnkey PCB Assembly Manufacturing in China is a smart choice for businesses looking to streamline their electronics production. By outsourcing the entire process to experienced manufacturers, you can save time, reduce costs, and ensure high-quality results. Whether you’re a startup or an established company, turnkey PCB assembly can help you stay competitive in today’s fast-paced market.

Ready to get started? Partner with a trusted turnkey PCB assembly provider in China and take your electronics production to the next level.

Recent Comments