Introduction to PCB Types

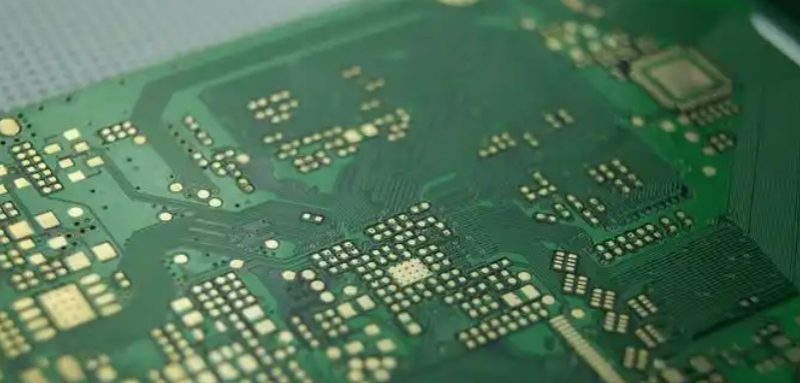

Printed circuit boards (PCBs) are the foundation of modern electronics, found in everything from smartphones to medical devices. Understanding different PCB types helps engineers and designers select the best option for their projects. This comprehensive guide covers all major PCB classifications, their unique characteristics, and ideal applications.

1. Main Types of PCBs by Material

1.1 Rigid PCBs – The Most Common Circuit Board

-

Composition: Fiberglass (FR4) or polyimide base

-

Key Features:

-

Excellent mechanical strength

-

Stable performance

-

Cost-effective for mass production

-

-

Common Uses:

-

Consumer electronics (TVs, computers)

-

Industrial control systems

-

Automotive electronics

-

1.2 Flexible PCBs (FPC) – Bendable Circuit Solutions

-

Composition: Polyimide or polyester film

-

Key Advantages:

-

Can bend and flex repeatedly

-

Lightweight and space-saving

-

Vibration resistant

-

-

Typical Applications:

-

Wearable devices

-

Medical equipment

-

Foldable smartphones

-

1.3 Rigid-Flex PCBs – Hybrid Circuit Technology

-

Unique Structure: Combines rigid and flexible sections

-

Benefits:

-

Reduced assembly complexity

-

Improved reliability

-

Space optimization

-

-

Primary Uses:

-

Aerospace systems

-

Military equipment

-

High-end medical devices

-

2. PCB Classification by Layer Count

2.1 Single-Sided PCBs – Basic Circuit Design

-

Structure: Copper traces on one side only

-

Advantages:

-

Lowest cost option

-

Simple manufacturing

-

-

Best For:

-

Simple electronics

-

Power supplies

-

LED lighting

-

2.2 Double-Sided PCBs – Intermediate Complexity

-

Design Features:

-

Conductive layers on both sides

-

Connected by vias

-

-

Applications:

-

Automotive dashboards

-

Industrial controls

-

Power converters

-

2.3 Multilayer PCBs – High-Density Solutions

-

Layer Configurations:

-

4-12 layers (standard)

-

Up to 50+ layers (advanced)

-

-

Critical Benefits:

-

High component density

-

Better signal integrity

-

EMI reduction

-

-

Usage Examples:

-

Smartphones

-

Network servers

-

Advanced computing

-

3. Specialized PCB Technologies

3.1 High-Frequency PCBs – For RF Applications

-

Key Materials: PTFE or ceramic-filled hydrocarbons

-

Performance Characteristics:

-

Low dielectric loss

-

Stable impedance

-

-

Industry Applications:

-

5G infrastructure

-

Radar systems

-

Satellite communications

-

3.2 Metal Core PCBs – Thermal Management Boards

-

Base Materials:

-

Aluminum (most common)

-

Copper

-

-

Thermal Advantages:

-

8-10x better heat dissipation

-

Prevents component overheating

-

-

Common Implementations:

-

LED lighting systems

-

Power electronics

-

Automotive lighting

-

3.3 HDI PCBs – Miniaturization Technology

-

Advanced Features:

-

Microvias (<150μm)

-

Fine pitch traces

-

Buried/blind vias

-

-

Design Benefits:

-

30-50% size reduction

-

Improved signal speed

-

-

Primary Markets:

-

Mobile devices

-

IoT products

-

Medical implants

-

4. PCB Surface Finishes Compared

| Finish Type | Thickness | Shelf Life | Cost | Best Applications |

|---|---|---|---|---|

| HASL | 1-40μm | 12 months | $ | Consumer electronics |

| ENIG | 0.05-0.2μm | 18 months | $$ | High-reliability systems |

| OSP | 0.2-0.5μm | 6 months | $ | Eco-friendly products |

| Immersion Silver | 0.1-0.3μm | 9 months | $$ | RF applications |

Choosing the Right PCB: Key Considerations

-

Operating Environment (temperature, moisture, vibration)

-

Signal Requirements (speed, frequency, integrity)

-

Space Constraints (size, weight limitations)

-

Budget Parameters (prototype vs mass production)

-

Thermal Management Needs (power dissipation)

Why Partner with Fuxinpcba for Your PCB Needs?

-

10+ years of PCB manufacturing expertise

-

Complete one-stop PCBA solutions

-

ISO 9001 certified quality systems

-

Fast prototyping (as quick as 24 hours)

-

Competitive pricing for all volume levels

Get a Free PCB Design Consultation Today! Our engineering team can help you select the optimal PCB type and manufacturing process for your specific requirements. Contact us now to discuss your project needs.

Recent Comments