Selecting the right PCB manufacturer in Shenzhen, China is crucial for ensuring product reliability, performance, and cost-efficiency. With Shenzhen being the global hub for electronics manufacturing, finding a trustworthy supplier can be overwhelming.

This guide will help you evaluate PCB manufacturers based on key factors like quality, certifications, production capabilities, and customer support—ensuring you make an informed decision.

Key Factors When Choosing a PCB Manufacturer in Shenzhen

1. Check Certifications & Reputation

✅ Certifications: Look for ISO 9001 (Quality Management), ISO 14001 (Environmental), UL, RoHS, and IPC standards compliance.

✅ Reputation: Read reviews on Alibaba, Global Sources, or Made-in-China and ask for client references.

✅ Experience: Manufacturers with 5+ years in the industry are more reliable.

2. Evaluate Technical Capabilities

✔ Layer Capacity: Can they produce 2-32 layers, HDI, or flexible PCBs?

✔ Advanced Technologies: Check for impedance control, blind/buried vias, high-frequency (RF) materials, and fine-pitch PCBs.

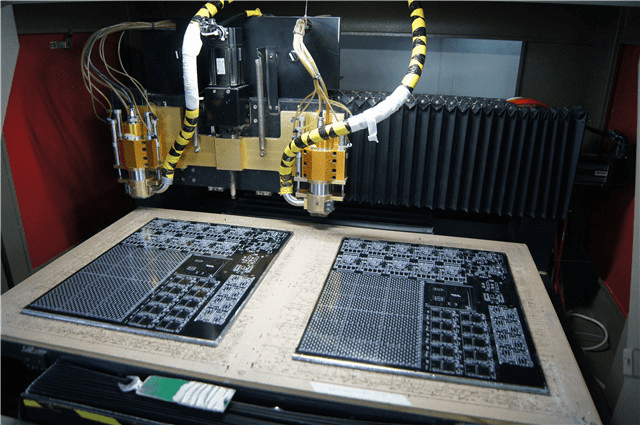

✔ Equipment: Modern facilities with AOI (Automated Optical Inspection), X-ray testing, and flying probe testers ensure precision.

3. Quality Control (QC) Standards

🔍 Testing Methods:

-

DFM (Design for Manufacturability) checks

-

Electrical testing (E-test, flying probe)

-

Thermal & reliability testing

📊 Quality Reports: Reliable manufacturers provide yield rates and defect analysis.

4. Design & Engineering Support

🛠 DFM Feedback: A good manufacturer will optimize your design for cost and performance.

⚡ Prototyping Services: Fast 24-72 hour prototypes help validate quality before mass production.

5. Request Samples for Evaluation

📦 Inspect:

-

Surface finish (ENIG, HASL, immersion silver)

-

Hole plating quality & solder mask alignment

-

Overall durability & electrical performance

6. Production Capacity & Lead Times

⏳ Prototype Lead Time: 1-5 days (for quick-turn orders).

🏭 Mass Production Lead Time: 2-3 weeks (depending on complexity).

📈 Scalability: Ensure they can handle small batches and large volumes.

7. Cost vs. Value (Avoid Cheap, Low-Quality Options)

💰 Get Detailed Quotes: Compare tooling, testing, and shipping costs.

⚠ Beware of Extremely Low Prices: They may indicate poor materials or shortcuts in production.

8. After-Sales Support & Warranty

🛡 Defect Policy: Check if they cover delamination, broken circuits, or soldering issues.

📞 Customer Service: Test their response time and problem-solving approach.

9. Visit the Factory (If Possible)

🏭 Factory Audit Checklist:

-

Clean and organized production lines

-

Skilled workforce & automated machinery

-

Compliance with safety & environmental standards

10. Check Customer Case Studies

📂 Ask for examples of past projects (e.g., automotive, medical, IoT, or high-speed PCBs).

Final Tips for Choosing the Best PCB Supplier

🔹 Start with a small trial order before committing to large volumes.

🔹 Negotiate clear contract terms (quality standards, lead times, defect liability).

🔹 Consider a sourcing agent if you need help with logistics and quality control.

Conclusion

Choosing the right PCB manufacturer in Shenzhen requires balancing quality, cost, lead time, and support. By following this guide, you can avoid common pitfalls and partner with a supplier that meets your project’s needs.

Need help finding a reliable PCB manufacturer? Contact us for verified supplier recommendations! 🚀