What Is PCBA? Definition and Meaning

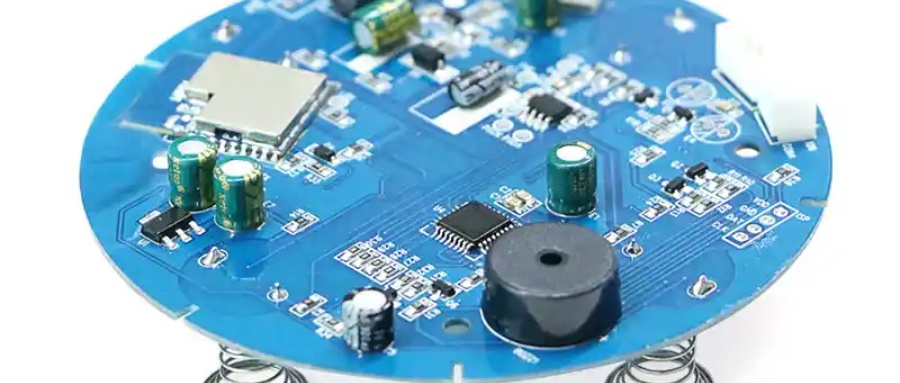

PCBA (Printed Circuit Board Assembly) refers to the process of soldering and mounting electronic components onto a bare PCB (Printed Circuit Board). A PCB serves as the foundation for electronic circuits, while a PCBA is the functional, assembled version ready for integration into devices.

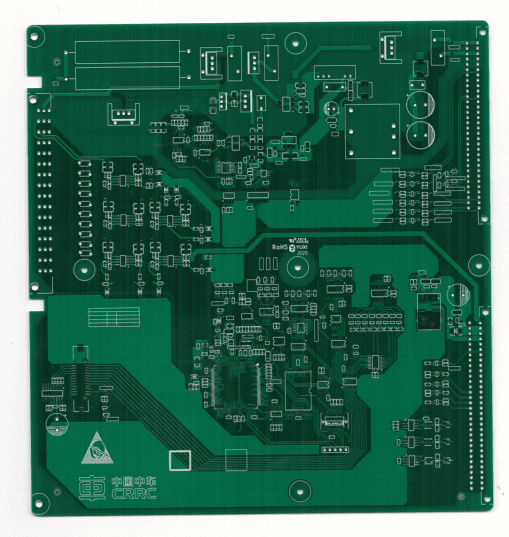

Key Difference: PCB vs. PCBA

- PCB = Blank circuit board (no components)

- PCBA = Fully assembled board (components mounted and soldered)

How Does PCBA Work? The Manufacturing Process

PCBA manufacturing relies on high-precision automation and advanced machinery to ensure efficiency and reliability. Below are the 7 essential types of PCBA equipment and their roles:

1. Stencil Printer

- Function: Applies solder paste onto PCB pads.

- Process: A metal stencil aligns with the PCB, and a squeegee spreads solder paste for component attachment.

2. Dispensing Machine

- Function: Precisely deposits solder paste or adhesive.

- Advantage: No need for fixture changes, ideal for small-batch production.

3. Pick-and-Place Machine (SMT Mounter)

- Function: Automatically places surface-mount components onto PCBs.

- Key Feature: High-speed, high-accuracy robotic assembly.

4. Reflow Soldering Oven

- Function: Melts solder paste to permanently bond components.

- Critical Factor: Controlled temperature profiling ensures strong connections.

5. Inspection & Testing Equipment

- Tools Used: AOI (Automated Optical Inspection), X-ray, functional testers.

- Purpose: Detects defects like misalignments, soldering issues, or electrical faults.

6. Rework Station

- Function: Repairs defective PCBAs (e.g., replacing faulty BGA chips).

7. Cleaning Equipment

- Purpose: Removes flux residues (if not using no-clean solder).

- Methods: Ultrasonic cleaning with specialized solvents.

Why Is PCBA Important in Electronics?

PCBA is the core of all modern electronics, including:

✔ Computers (motherboards, SSDs, GPUs)

✔ Consumer devices (smartphones, TVs, wearables)

✔ Industrial systems (automation controls, medical devices)

PCBA’s Role in Product Performance

- Determines speed, efficiency, and reliability of electronic devices.

- Impacts product lifespan—poor-quality PCBA leads to failures.

- Enables miniaturization (e.g., compact IoT devices).

Fuxin PCBA: Your Trusted PCBA Manufacturing Partner

At Fuxin PCBA Technology Co., Ltd, we provide end-to-end PCB assembly services, including:

✅ PCB fabrication & design

✅ Component sourcing & procurement

✅ High-precision SMT & through-hole assembly

✅ Rigorous quality testing (AOI, X-ray, functional tests)

✅ Fast turnaround & competitive pricing

Need a quote? Send us your Gerber files and BOM for a response within 3 business days!

Recent Comments