Printed Circuit Board Assembly(PCBA ) is commonly used as a key technology in manufacturing various electronic products. Fuxin Electronic Technology Co., Ltd. will provide a comprehensive introduction to PCBA, and its special features helping everyone to better understand this interesting field.

What is PCBA?

It is the process of attaching and soldering electronic components onto a printed circuit board (PCB), using surface mount technology (SMT) or through-hole technology (THT),PCBA, short for Printed Circuit Board Assembly. This process creates an electronic device with specific functions. In simpler terms, PCBA involves assembling different electronic components onto a printed circuit board.

Characteristics of Printed Circuit Board Assembly(PCBA ):

In the modern electronics industry, Printed Circuit Board Assembly (PCBA) is widely used as a key technology for manufacturing various electronic products. Fuxin Electronic Technology Co., Ltd. provides a comprehensive introduction to PCBA and its special features, aiming to help everyone gain a better understanding of this interesting field.

-

High Integration and Precision

With the fast growth of electronic technology, electronic products are increasingly focused on being smaller, lighter, and more powerful. As a result, PCBA needs to be highly integrated and precise to fulfill the size, weight, and performance demands of modern electronic products. By using advanced manufacturing methods, electronic components are closely positioned on the PCBA, allowing for highly integrated designs.

-

Systemization and Integration

Printed Circuit Board Assembly(PCBA ) combines different electronic components on a circuit board, integrating electronic systems. This simplifies design, reduces development time, and improves the reliability and stability of the entire electronic system. Integrated design also helps lower production costs and improve efficiency, giving a competitive advantage in a competitive market.

-

Customizability

PCBA offers a high level of customization, allowing the design of circuit board assembly solutions that meet specific functional requirements for different electronic products. Whether it’s consumer electronics like mobile phones, tablets, and smart wearables, or industrial electronics such as instruments, medical devices, and communication equipment, PCBA can be customized to meet the needs of various fields.

-

Environmental Friendliness

Protecting the environment is a big concern worldwide, and PCBA also cares about being environmentally friendly when manufacturing. We use solder without lead, materials for solder masks that are free of halogen, and we recycle electronic products that are no longer used. This helps reduce our impact on the environment. Many countries and regions have rules that require electronic product makers to use materials and processes that are kind to the environment. This raises the environmental standards for the industry as a whole.

-

High Reliability and Stability

We make sure that electronic components are of high quality and work well by having strict systems for managing quality, using advanced testing equipment, and following set processes. After we install the electronic components, we test and check the PCBA thoroughly to make sure it works well in different environments. This means that the electronic product is reliable and stable, and it will last longer and work better.

-

Easy Maintenance and Upgrades

The design and manufacturing of PCBA take into account the need for maintenance and upgrades. If a certain electronic component stops working, it can be easily replaced without affecting the rest of the system. Additionally, if an upgrade is needed for the electronic product, it can be done by replacing or adding new components without changing the system’s design.

-

Quick Response and Production

By using advanced manufacturing processes and automated production lines, PCBA can complete a large number of production tasks quickly. This allows PCBA manufacturers to respond quickly to changes in market demand and introduce new electronic products. Furthermore, the automation and intelligence in the PCBA production process continue to improve, resulting in lower production costs, improved efficiency, and higher product quality.

What is the manufacturing of Printed Circuit Board Assembly(PCBA )?

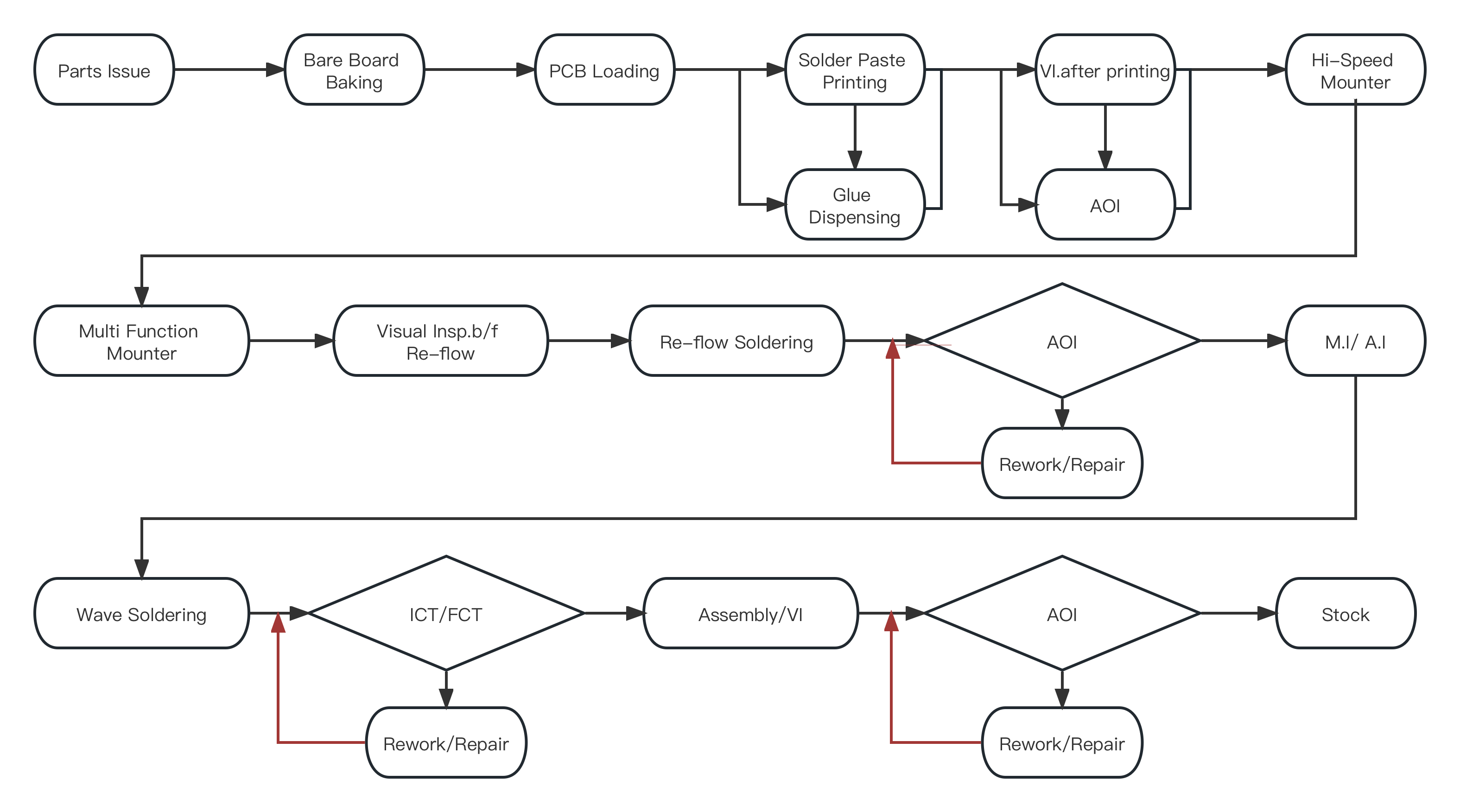

The PCBA production process can be divided into a few main steps:

- SMT chip processing: This is a method of integrating components on PCB boards without drilling holes.

- DIP plugin processing: This is another method of integrating components on PCB boards that requires inserting component pins into pre-drilled holes.

- PCBA testing: This step involves testing the assembled PCB boards.

- Finished product assembly: This step involves assembling the final product.

Both SMT (Surface Mounted Technology) and DIP (Dual In-line Package) are methods of integrating components on PCB boards. The main difference is that SMT does not require drilling holes on the PCB, while DIP requires inserting the pins of the components into pre-drilled holes.

SMT (Surface Mounted Technology)

Surface Mount Technology is mainly used to place small components on PCB boards using placement machines. The production process includes PCB board positioning, solder paste printing, placement machine mounting, reflow soldering, and final inspection. With advancements in technology, SMT can also be used to place larger components, such as bigger mechanical parts on motherboards. The quality of solder paste and printing, as well as component positioning and size, are important factors for SMT integration.

DIP (Dual In-line Package)

DIP stands for “Dual In-line Package,” which involves inserting components into PCB boards. DIP is used when the component size is larger and not suitable for surface mounting, or when the manufacturer’s production process cannot utilize SMT technology. Currently, there are two implementation methods in the industry: manual insertion and robotic insertion. The main production process for DIP includes adhesive application (to prevent solder from spreading to unwanted areas), component insertion, inspection, wave soldering, stencil cleaning (to remove residue from the reflow process), and final inspection.

What does the PCBA do?

The PCBA (Printed Circuit Board Assembly) is important for many industries,as it supports electronic product development. PCBA circuit boards are widely used in manufacturing and development of electronic products. Here are some main application areas:

- Consumer Electronics: PCBA circuit boards are widely used in devices like TVs, smartphones, tablets, speakers, and gaming consoles. These circuit boards enable different functions in these devices.

- Communication Equipment: PCBA circuit boards are crucial components in wireless base stations, fiber optic communication equipment, satellite communication equipment, and other communication devices. They support data transmission and communication functions.

- Automotive Electronics: Modern cars use many electronic devices, such as Engine Control Units (ECUs), in-car entertainment systems, and safety systems. These devices need PCBA circuit boards to perform different functions.

- Medical Equipment: The medical field needs electronic devices. Monitoring equipment, surgical instruments, medical imaging equipment, and other medical devices all use PCBA circuit boards to enable different medical functions.

- Industrial Control Equipment: PCBA circuit boards are used in machines and systems that control and automate industrial processes, like Programmable Logic Controllers (PLCs), sensors, and industrial robots. These circuit boards help with controlling and monitoring different functions.

How do you test for PCBA?

https://www.fuxinpcba.com/pcb-assemblypcba-testing/

What is different PCB and PCBA?

How to choose PCB Assembly manufacturer?

Our PCBA service

Fuxin provides customers with leading position and experience in advanced PCB assembly technology, mature processes and comprehensive services. From prototyping, low-volume multi-variety to high-volume global manufacturing, we provide printed circuit board assembly services to customers around the world. Fuxin is a recognized professional contract manufacturer that develops the latest PCBA and surface mount (SMT) capabilities, providing customers with one-stop quick turn services.

Recent Comments